Table of contents:

The Critical Role of PCB Gold Fingers in Life-Saving Equipment

How Multilayer PCB Design Enhances Medical Imaging Technology

Ensuring Reliability in Wearable Health Devices with Golden Finger PCBs

Double Layer PCB Innovations Driving the Future of Medical Electronics

The Critical Role of PCB Gold Fingers in Life-Saving Equipment

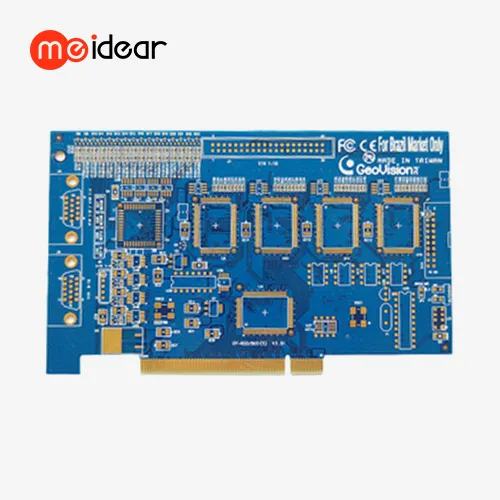

In the realm of medical technology, where every microsecond counts, the reliability of electronic components is paramount. Gold finger PCBs have emerged as a game-changer, offering unparalleled conductivity and resilience in critical medical equipment. These specialized boards, crafted by expert multilayer PCB manufacturers, feature gold-plated connectors that ensure seamless data transmission and power distribution. The durability of gold fingers is particularly crucial in devices like defibrillators and patient monitoring systems, where consistent performance can mean the difference between life and death. As healthcare facilities seek robust pcb assembly solutions, the adoption of gold finger PCBs in life-support machines and diagnostic tools continues to rise, underlining their indispensable role in modern medicine.

How Multilayer PCB Design Enhances Medical Imaging Technology

The field of medical imaging has been revolutionized by the advent of multilayer PCB technology. These sophisticated boards, produced by leading multilayer PCB manufacturers, enable the development of more compact and powerful imaging devices. MRI machines, CT scanners, and ultrasound equipment now benefit from the increased circuit density and improved signal integrity offered by multilayer PCBs. The ability to stack multiple layers of circuitry allows for more complex designs, resulting in sharper image resolution and faster processing speeds. As healthcare providers demand more accurate and efficient diagnostic tools, the pcb assembly service industry responds with innovative solutions that push the boundaries of what's possible in medical imaging technology.

Ensuring Reliability in Wearable Health Devices with Golden Finger PCBs

The burgeoning market for wearable health devices has created new challenges for PCB designers and manufacturers. Golden finger PCBs have proven to be an ideal solution for these compact, high-performance devices. Their superior durability and resistance to wear make them perfect for wearables that undergo constant movement and frequent connections. Multilayer PCB manufacturers are now focusing on developing ultra-thin, flexible boards that can conform to the ergonomic requirements of wearable technology. The pcb assembly service for these devices demands precision and reliability, ensuring that vital health data is accurately captured and transmitted. From fitness trackers to continuous glucose monitors, golden finger PCBs are at the forefront of the wearable health revolution.

Double Layer PCB Innovations Driving the Future of Medical Electronics

As medical devices become increasingly sophisticated, double layer PCBs are emerging as a cost-effective and efficient pcb assembly solution. These boards offer a balance between the simplicity of single-layer designs and the complexity of multilayer configurations. In portable medical devices, where space is at a premium, double layer PCBs provide the necessary functionality without compromising on size. Multilayer PCB manufacturers are innovating in this space, developing double layer boards with enhanced thermal management and EMI shielding properties. This advancement is particularly beneficial for devices like portable ECG monitors and insulin pumps, where reliability and miniaturization are equally important. The future of medical electronics looks bright as pcb assembly services continue to refine and perfect double layer PCB technologies.

The integration of advanced PCB technologies in medical devices marks a significant leap forward in healthcare innovation. From life-saving equipment to wearable health monitors, the impact of precision-engineered PCBs is profound and far-reaching. Multilayer PCB manufacturers are at the forefront of this revolution, constantly pushing the boundaries of what's possible in circuit board design and fabrication. As the medical industry continues to evolve, the demand for specialized pcb assembly solutions will only grow. The synergy between cutting-edge PCB technology and medical innovation promises a future where healthcare is more accurate, efficient, and accessible than ever before. The ongoing advancements in PCB design and manufacturing are not just enhancing medical devices; they're transforming the very landscape of patient care and medical diagnostics.

Comments

Post a Comment